Do you know the importance of air filters in industrial settings?

Maintaining air quality in industrial environments is essential for:

-Worker safety

-Adhering to environmental laws

-Extending the life of machinery

The use of filter cages and sleeve holders is crucial to attaining efficient air filtration.

These constituents are essential for the proper functioning and longevity of filtration systems.

They have a direct effect on the air we filter.

What are Filter Sleeve Holders and Cages?

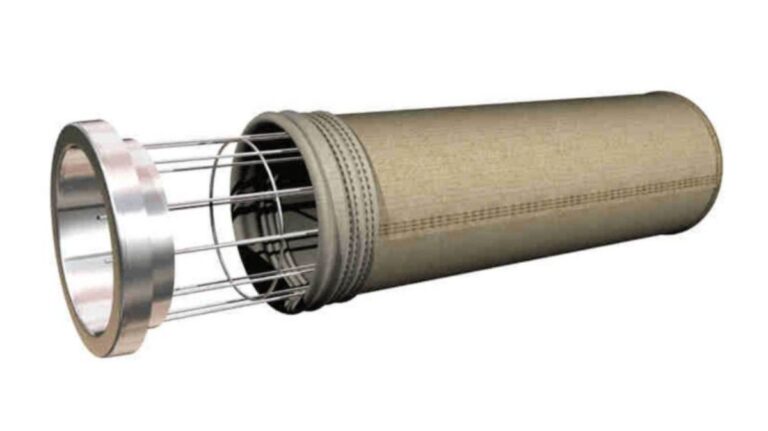

In industrial air filtration systems, cages and filter sleeve holders play crucial roles. The filter bags that collect dust, pollutants, and other airborne particles rely on their joint support and security. These parts are crucial to air filtration systems because without them, the systems would not work as well.

Filter sleeves or bags are held in position within the filtration unit by filter sleeve holders. By checking the alignment and integrity of the filter material, they guarantee that unfiltered air will not seep out or circumvent the filter. Even a little misalignment can create pollution and worse air quality, therefore this alignment is critical.

The filter bags are structurally supported by the cages, on the other hand. They keep the filter bags from bursting due to the air pressure and are usually constructed of metal. An important part of the filtration system’s overall effectiveness is the cages’ design and material.

More effective filtration and longer filter life can be attained, for instance, by designing the cage so that air flows evenly throughout the filter medium.

Why Quality Filter Sleeve Holders and Cages are Important?

A system’s ability to filter air is proportional to the quality of its filter sleeve holders and cages. Some of the benefits of using high-quality components are:

Optimized Filtration Performance:

Filter sleeve holders and cages that are well-made and designed keep the filter media in the right place and provide complete support. This improves the air filtration system’s overall performance by better capturing dust and contaminants.

Longer Filter Life:

Changing out filter bags, particularly in big industrial systems, may be rather costly. By providing steady support and minimizing wear and tear, high-quality filter sleeve holders and cages aid in the extension of the filter bags’ lifespan. Not only does this cut down on operating expenses, but it also keeps downtime for replacing filters to a minimum.

Decreased Chances of System Failure:

Filter sleeve holders and cages that are not well-made or have poor design may cause system failures like filter bags collapsing or unfiltered air leaking out. Major disruptions and expensive repairs may follow. You may lessen these dangers and make sure the air filtration system runs continuously by investing in high-quality components.

Meeting Requirements:

Strict air quality rules affect several sectors. To avoid fines and other penalties, make sure your air filtration system meets or exceeds these specifications by using high-quality filter sleeve holders and cages.

Types of Filter Sleeve Holders and Cages

Filter sleeve holders and cages come in a variety of styles, each optimized for a different set of parameters. In order to choose the correct parts for your air filtration system, it is helpful to understand the distinctions between these kinds.

Standard Filter Sleeve Holders:

The most popular type of holders used in industrial air filtration systems are standard filter sleeve holders. Their purpose is to keep filter bags in place safely, with the goal of keeping them in the correct position and reducing air leakage. Stainless steel and galvanized steel are common materials for standard holders because of their durability and resistance to corrosion and wear.

Specialized Filter Sleeve Holders:

Some sectors have specialized filtering needs that need industry-specific holders. Examples of situations where holders constructed of materials resistant to high temperatures are required include settings with very hot air. Holders coated to withstand chemicals are also useful in places where airborne pollutants might cause damage.

Standard Filter Cages:

Standard cages for air filtration are the most often employed in industrial settings. They make sure the filter bags will not collapse as pressure builds up. Most common cage materials are metal with protective coatings to stave against wear and corrosion.

Cages Made to Order:

In order to accommodate certain filtration systems, cages made to order are necessary. Cages like this may come in a wide variety of sizes, forms, and materials to meet the needs of any given application. When regular cages are not provide protection from things like dust, dampness, or chemicals, a custom cage is a good investment.

Selecting the Right Filter Sleeve Holders and Cages

To get the most out of your air filtration system and keep it running for a long time, you need to choose the correct cages and holders for the filter sleeves. Listed below are a few important considerations:

Material:

The holders and cages’ materials should be suitable for the intended application. Stainless steel, on the one hand, and galvanized steel, on the other, are great choices for places that get a lot of moisture or have chemicals that might rust them.

Size:

Make sure the cages and holders are the right size for your filter bags. Air leakage, decreased filtration effectiveness, and higher filter bag wear might result from components that are not appropriately sized.

Design:

Thirdly, the design of the cages and holders should be such that air flows evenly and there is no resistance. Better filtering results from using the whole surface area of the filter bag.

Longevity:

Think about how long the holders and cages will last thanks to the materials and coatings utilized. You will not have to repair the components as often if you choose high-quality materials and coatings.

Compatibility:

Make sure the cages and holders work with the filter bags and system you have before purchasing. This involves thinking about things like the air’s temperature and pressure as well as the specific dust or contaminants that need to be filtered.

How to Maintain Filter Sleeve Holders and Cages

To keep the air filtration system running smoothly and for as long as possible, it is essential to regularly maintain the filter sleeve holders and cages. Here are a few pointers on upkeep:

Periodic Checks:

Make sure to check the holders and cages for any indications of wear, corrosion, or damage on a regular basis. Problems may be better managed if caught early on, before they escalate.

Cleaning:

To avoid corrosion and other damage, make sure the holders and cages are clean at all times.

Timely Replacements:

Be sure to replace any worn-out or broken holders and cages as soon as possible to keep the air filtration system running smoothly.

Lubrication:

Lubricating moving components may make them run smoothly and keep them from wearing down.

Final Thoughts

Filter sleeve holders and cages are essential parts of industrial air filtration systems. They are critical in ensuring that filter bags are correctly supported, aligned, and fastened, resulting in increased filtering efficiency, longer filter life, and a lower chance of system failure.

By using the proper holders and cages and conducting regular maintenance, you can improve the efficiency and lifetime of your air filtration system, resulting in cleaner air and a safer working environment.